Production Process

JIN RED PEPPER HOUSE

thoroughly manages all the processes

by HACCP from selection and

warehousing of raw materials to

manufacturing, packaging, and storage

01

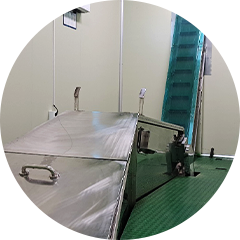

Input

Washed dried peppers are input

02

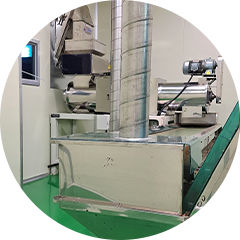

Air cleaning

Air is sprayed to remove foreign substances

03

Screening

It is the process of visual screening to remove foreign substances as a second phases

04

Separating seed, sorting, crushing

The seeds are separated and crushed first

05

Mixing

Mix the crushed skin and seeds from the previous stage

06

Roll mill (Grinding)

Milling chili powder in 9 phases

07

Particle Selection

Selecting the ground chili powder for the desired size

08

Dry

Dry it at high temperature for hygiene control of milled red pepper powder

09

Detection of Iron powder

A powerful magnet is used to remove any iron powders in the red pepper powder

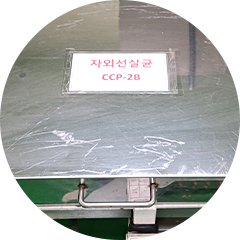

10

Ultraviolet sterilization

Ultraviolet is used for sterilization

11

Packaging

The products are packaged in a hygienic packaging facility.

12

Metal Detection

Final quality control of packaged products with a metal detector.